Explore Our Range of Gabion Machine

Built for harsh environments, our gabion machines deliver high output and stable performance for all types of protection work.

With adjustable mesh sizes and wire diameters, both heavy-duty and horizontal models can meet diverse project demands.

They’re widely used in riverbank protection, highway slopes, mining sites, and custom gabion box production projects.

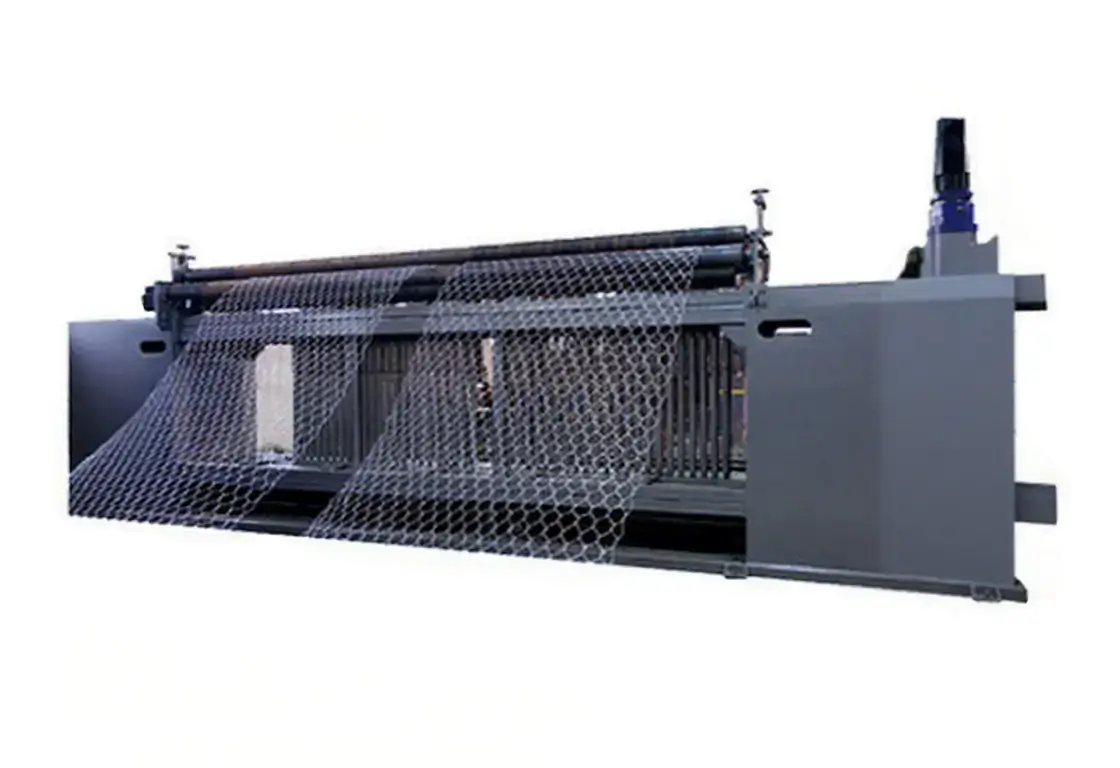

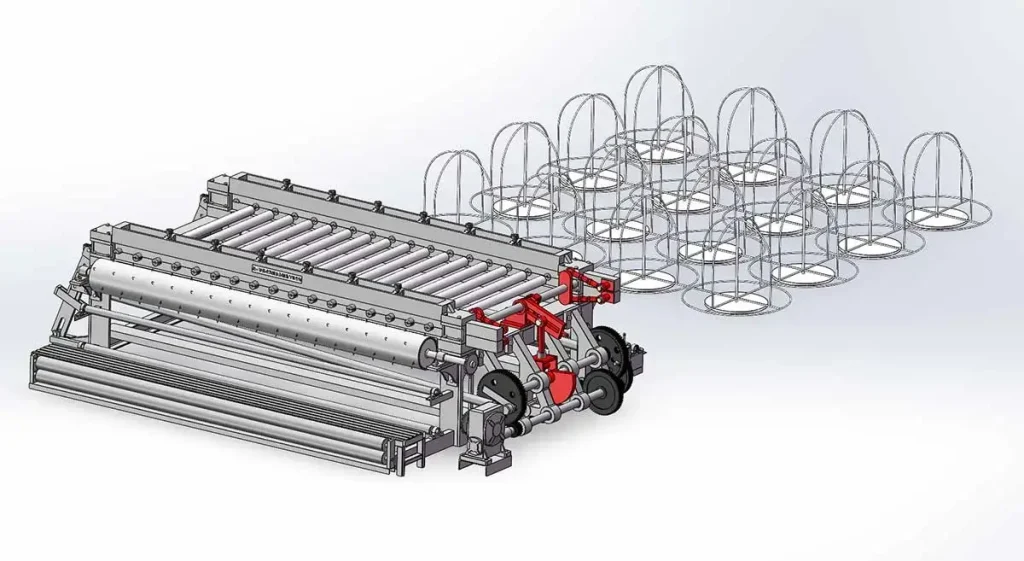

Horizontal Gabion Mesh Machine

Horizontal model with standard motor — compact, cost-effective, and space-saving.

Horizontal PLC Gabion Making Machine

Horizontal model with PLC servo — offers automation, low cost, and a small footprint.

Heavy Duty Gabion Box Making Machine

Vertical model with standard motor — ideal for thick wire diameter and higher output.

Heavy Duty PLC Gabion Box Machine

Vertical model with PLC servo — supports thick wire, fast speed, and intelligent automation.

Choose the Ideal Gabion Machine for Your Project

The right gabion machine helps you work faster, reduce costs, and deliver durable gabion mesh boxes.

We offer both horizontal and vertical models, as well as mechanical and PLC-controlled options — all configured to fit your specific project.

Horizontal vs Heavy-Duty Vertical Gabion Machine

| Feature | Horizontal Gabion Mesh Machine. | Heavy Duty Gabion Mesh Machine. |

|---|---|---|

| Structure | Horizontal weaving, low working height, stable operation, compact footprint (approx. 5.5–7.5 tons). | Vertical weaving, ample floor space, but requires lifting equipment; heavier overall weight (13–22 tons). |

| Production Speed | 20–50 m/h | 50–225 m/h |

| Wire Diameter | 1.0 mm – 3.0 mm | 1.0 mm – 4.0 mm |

| Material Compatibility | Works with standard galvanized, PVC-coated, and stainless steel wires. | Handles high-strength wires such as Galfan alloy and high-carbon galvanized steel. |

| Operation | Simple structure, easy to maintain, requires 2 operators. | More complex maintenance also requires 2 operators. |

| Power Consumption | Lower power demand (7.5–11 kW). | Higher power consumption (11–22 kW). |

| Investment Cost | Lower initial investment (USD 10,000–20,000). | Higher initial investment (USD 30,000–50,000). |

Mechanical Type vs. PLC Controlled Gabion Machine

| Feature | Mechanical Gabion Mesh Machine | PLC Gabion Mesh Machine |

|---|---|---|

| Control System | Gear and linkage system; parameter changes require manual adjustment. | Automated PLC + touchscreen; one-click change for twist type (single/double/triple). |

| Production Speed | Medium-speed (20–50 m/min) | High-speed (50–225 m/h) |

| Noise & Environment | Noise >85 dB, minimal dust control. | Noise <75 dB, a cleaner working environment. |

| Maintenance Cost | Simple setup but prone to wear; gears require frequent replacement. | Enclosed lubrication system reduces wear and dust, extending part life. |

| Investment Cost | Lower upfront cost (USD 10,000–30,000) but higher labor and maintenance costs. | Higher initial cost (USD 40,000–100,000), but up to 50% labor savings and lower long-term expenses. |

Final Recommendation

| Comparison | Horizontal Machine | Vertical Machine | Mechanical | PLC-Controlled |

|---|---|---|---|---|

| Project Scale | Small to medium (≤5,000 boxes) | Large-scale (≥20,000 boxes) | Temporary or small-scale (≤3,000 boxes) | Long-term, high-volume (≥20,000 boxes) |

| Budget Range | Up to USD 30,000 | From USD 40,000 | Up to USD 30,000 | From USD 40,000 |

| Labor Dependence | 2 operators | 2 operators | Skilled team (manual control) | Single operator (automated control) |

Short-term, small project? → Choose a mechanical horizontal gabion machine.

Large-scale, high standard? → Choose a heavy-duty PLC vertical machine.

Are you unsure which model best suits your project’s conditions and budget? We will help you choose the correct configuration.

Contact us now!

Gabion Machine Applications

Flood Control Mesh Barriers

Flood control requires robust, adaptable, and durable solutions. Gabion mesh machines produce Gabion cages that, when filled with rock, form barriers to slow and redirect rising waters.

Used in major flood prevention projects, gabion barriers have helped reduce water damage by over 40% compared to traditional methods—proving their value in large-scale flood defense.

Slope Support Solution

Landslides and unstable slopes are a common safety risk in mining, road construction, and infrastructure projects.

Gabion mesh machines help build strong wire-mesh retaining walls that improve safety and prevent slope failures.

Used in open-pit mines, gabion cages have reduced slope accidents by up to 50%—minimizing downtime and protecting workers.

Eco-Friendly Gabion Mattress

Gabion mesh machines build flexible, energy-absorbing barriers that protect shorelines and reduce erosion.

During a major wetland restoration project in China, gabion cages produced reduced soil loss by 60%, allowing diverse plant communities to establish and enhancing water quality, thereby demonstrating the effectiveness of gabion technology in promoting sustainable ecosystem recovery.

Coastal Erosion Protection Mesh

Coastal zones constantly battle waves, tides, and storm surges. Gabion mesh machines build flexible, energy-absorbing barriers that protect shorelines and reduce erosion.

Compared to traditional seawalls, gabion structures can reduce maintenance costs by over 30%, offering both improved performance and long-term savings.

Gabion Machine Use Cases

From infrastructure to civil engineering, our gabion machines help contractors build strong, long-lasting gabion mesh.

Used by companies across India, Africa, Southeast Asia, and the Middle East, they’re a trusted choice in over 30 countries worldwide.

Customized Horizontal Gabion Mesh Machine for Riverbank Protection

For a riverbank project using oversized riprap, standard mesh sizes and wire gauges weren’t strong enough.

We customized the machine with a larger mesh size (280 × 300 mm) and switched to 3.0 mm stainless steel wire to handle heavier loads.

To keep costs down without losing power, we replaced the usual servo motor with a three-phase induction motor—strong enough to twist thick wire reliably, while cutting equipment costs.

PLC Horizontal Gabion Mesh Machine for Space-Limited Projects

For a new gabion production site with limited floor space, the project demanded high-precision mesh output without bulky equipment.

We delivered a PLC-controlled horizontal machine that replaces traditional gear-pendulum drives, cutting machine size by over 30%.

To further reduce space use, we integrated a dual-tier pay-off frame for bobbins and an overhead wire straightening system, freeing up the mesh pressing zone and making the layout far more efficient.

Vertical Heavy‑Duty Gabion Mesh Machine for Emergency Projects

When urgent slope and riverbank stabilization is needed — and budgets are tight — speed and output matter most.

This mechanical vertical model delivers high-volume production at lower cost. It runs faster than horizontal machines and skips the complexity of PLC systems, making it ideal for rapid deployment in emergency settings.

PLC Vertical Heavy‑Duty Gabion Machine for Scalable Infrastructure Projects

For large-scale infrastructure and erosion control projects that require a steady supply of gabion mesh, long-term reliability is crucial.

This PLC-controlled vertical model delivers consistent, high-speed output with minimal operator involvement. Its automated control system simplifies both operation and maintenance—perfect for manufacturers looking to scale up.

Whether for flood control, slope stabilization, or landscape design, our gabion mesh machines provide reliable and efficient solutions worldwide.

Why Choose Our Gabion Machine?

Work directly with a trusted gabion machine manufacturer in China — get competitive factory pricing, long-lasting machines, and responsive technical support every step of the way.

Factory Direct Pricing

Cut out intermediaries by ordering straight from our gabion mesh machine factory, and maximize your budget without compromising quality.

Tailored Gabion Machine Solutions

Get custom-configured gabion mesh machines built to your exact mesh size, wire diameter, and production capacity requirements.

Built to Global Standards

All our gabion machines comply with ISO and CE safety and performance regulations, ensuring reliable, long-lasting operation worldwide.

Automated High‑Speed Lines

Deploy high‑efficiency, PLC‑controlled gabion mesh production lines that boost output, minimize manual labor, and reduce lead times.

Rapid Delivery & On‑Site Setup

We help your machinery get up and running quickly through fast production delivery and comprehensive after-sales service.

Dedicated After‑Sales Support

Access technical assistance, genuine spare parts, and hands‑on training to keep your gabion mesh equipment operating at peak performance.

Explore Our Gabion Machine Manufacturing Capabilities

Our gabion machine manufacturers use modern CNC machining centers, automatic cutting machines, and advanced assembly lines to ensure every gabion wire mesh machine meets your project’s most challenging demands.

From raw alloy billets to ready-to-assemble components, all core machining is completed in-house under strict ISO 9001 quality standards.

Customization of Gabion Machine

Every component of the gabion machine can be customized to meet project requirements precisely.

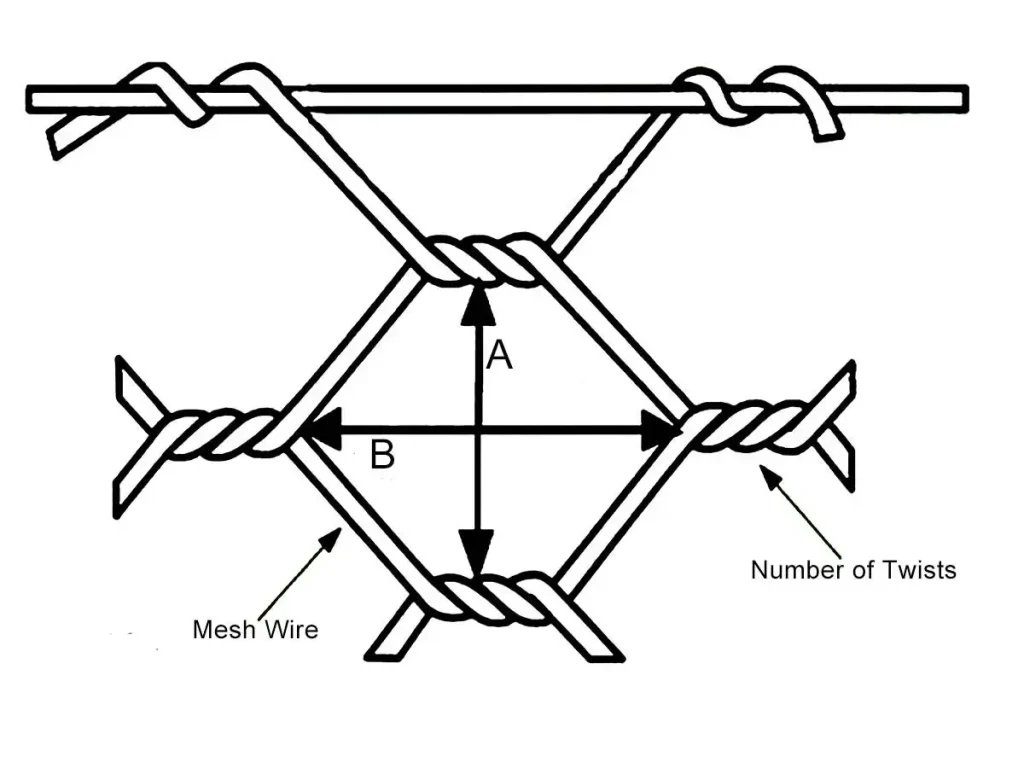

Flexible Mesh Size Options

We offer standard mesh sizes, including 60×80 mm, 80×100 mm, and 100×120 mm, which are ideal for slope protection and flood control.

Custom mesh sizes are also available to suit unique project requirements.

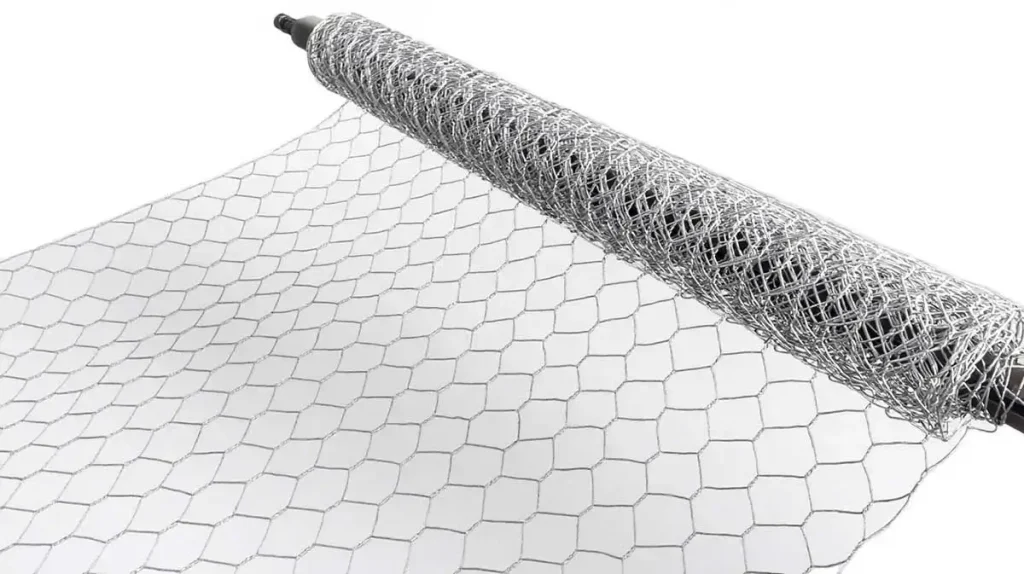

Wire Diameter Compatibility

Our machines handle various wire types—including galvanized, stainless steel, PVC, and PET wires.

Standard wire diameter ranges from 1 to 3 mm. For larger mesh openings, we can customize the machine to twist 4 mm or even 5 mm wire.

Customization Max Mesh Width

Standard maximum mesh widths include 2 m, 3 m, and 4 m, with custom options available for wider formats.

Each machine supports multiple-mesh weaving—for example, a 4 m model can simultaneously produce four 1 m-wide panels.

Customization Twist Typ

5-twist: Maximum strength and stability for fast-flowing rivers or high-scour zones.

3-twist: A well-balanced structure ideal for slope protection and dam reinforcement.

1-twist: High flexibility for soft ground or areas with heavy soil movement.

Machine Appearance & Branding

As the original manufacturer, we fully own the design and technology of our gabion machines.

We support custom machine colors and logos to align with your corporate identity and brand recognition.

Customization Control System

Our Gabion Machines come with a standard electrical cabinet, tailored to your local power supply.

For advanced automation, upgrade to a PLC control system—offering precise mesh output, auto start/stop functions, and intuitive operation.

Let’s build the right gabion mesh machine for your needs — contact us today to streamline your production and save costs.

How to Order Your Gabion Machine

We keep the process simple. From your first message to delivery and setup, we’re with you every step of the way.

Tell Us What You Need

Please send us your project requirements. We will promptly identify the most suitable machine for your needs.

Get a Detailed Quote

You’ll receive a clear offer with pricing, configuration options, and lead time—all from our factory.

Confirm the Details

Once all details have been confirmed, we will finalize the gabion machine specifications and sign a contract.

Manufacturing in Progress

Your machine goes into production. We’ll update you with photos and keep a close eye on quality.

Secure Packing & Delivery

We pack the machine safely and arrange shipping to your site—by sea, rail, or road, as needed.

Set up Help & Ongoing Support

Need help during installation? We offer remote or on-site assistance and are always here to answer any questions that may arise later.

Working Process of Gabion Machine

This section outlines the operating steps for the horizontal gabion making machine for your reference.

You can get the operator’s manual for our gabion mesh machines here.

Gabion Machine FAQs

Find faq about our gabion machine and export services.

Get Factory Price for Your Gabion Machine

We’re the original manufacturer — factory direct, no trading companies involved.

Our engineers will respond within 24 hours with a quote and professional advice.

Resources

Heavy Duty Gabion Mesh Machine

Driven by ordinary motor with a vertical structure, supports thicker wire weaving and higher efficiency.

Read moreHeavy Duty Gabion Mesh Machine

Driven by ordinary motor with a vertical structure, supports thicker wire weaving and higher efficiency.

Read moreHeavy Duty Gabion Mesh Machine

Driven by ordinary motor with a vertical structure, supports thicker wire weaving and higher efficiency.

Read more