Hexagonal Chicken Mesh Machine Description

Stable and Efficient Chicken Mesh Machine

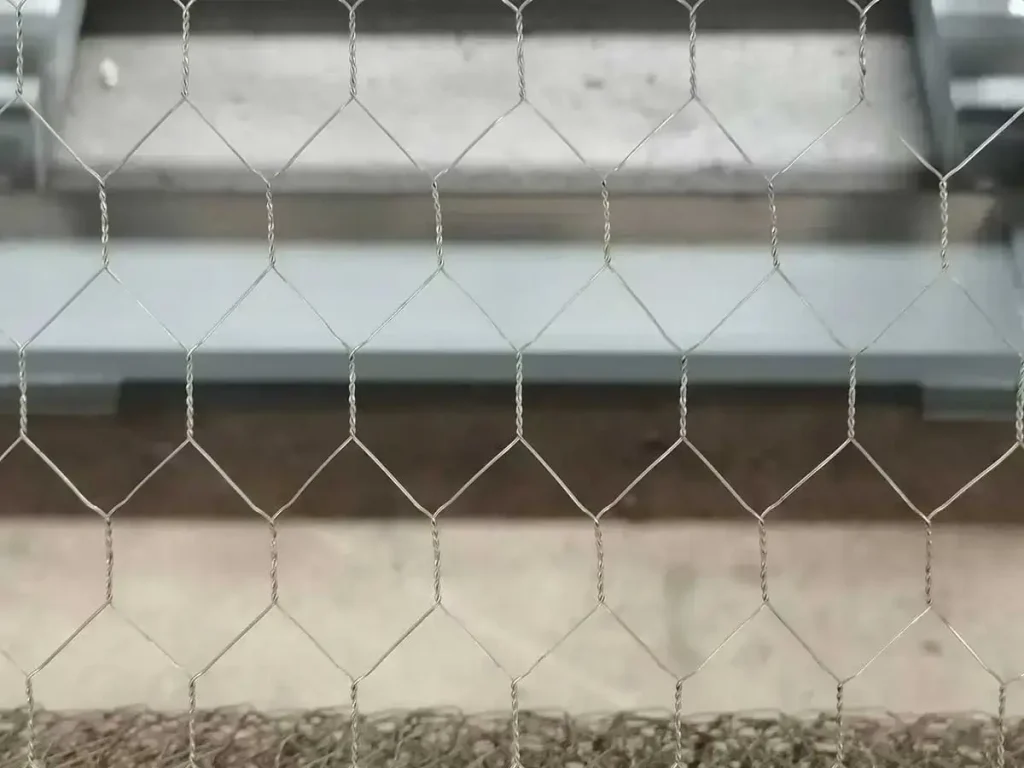

The chicken mesh machine, also called a hexagonal wire mesh machine, produces mesh using a forward-reverse twist.

Powered by a single 2.2 kW motor, it’s highly energy efficient and cost-effective.

Core parts are made from high-quality cast iron and precisely processed with gantry milling for high accuracy, smooth running, low noise, and fast weaving.

It removes the spring-making step of traditional gabion machines, making operation easier and safer. An automatic stop function activates if the wire breaks, ensuring reliable, efficient production.

Chicken Mesh Machine Specifications

The key technical specifications of our mechanical chicken mesh machine include mesh size, wire diameter, max width, speed, motor power, weight, and dimensions. All customizable to your project needs.

| Parameter | Specification |

|---|---|

| Specifications | 1/2″ , 3/4″ , 1″ , 1/1/4″ , 1/1/2″ , 2″ , 3″ , 4″ |

| Wire Diameter | 0.38 – 2.0 mm |

| Max Mesh Width | 2000 mm , 3000 mm , 4000 mm |

| Number of Twists | 6 |

| Production Speed | 180 m/h |

| Motor Power | 2.2 kW |

| Weight | 3.0 – 3.5 t |

| Dimensions (L×W×H) | 4200×1500×1600 mm , 5200×1500×1600 mm , 6200×1500×1600 mm |

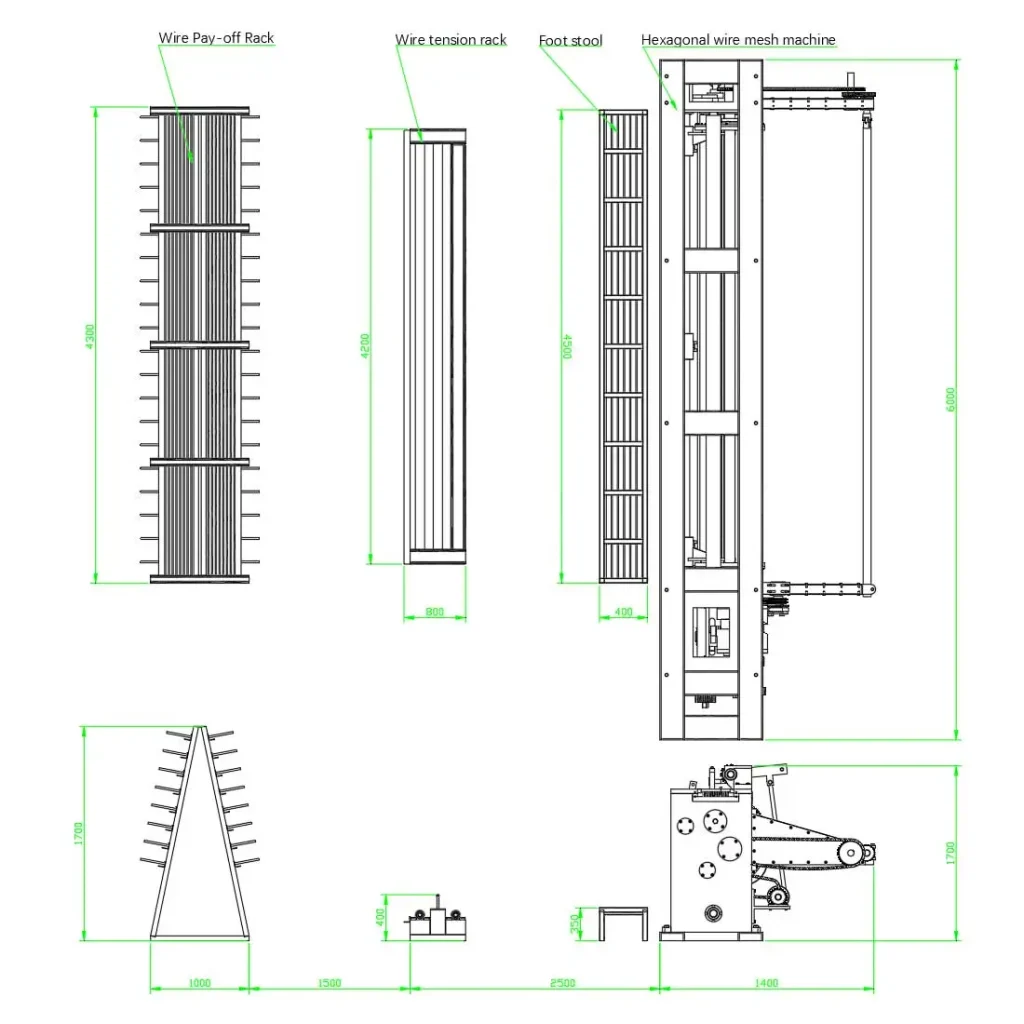

Chicken Mesh Machine Layout Drawing

The layout below helps illustrate the machine setup and workshop planning, showing key units like the chicken mesh machine, tension rack, and pay-off stands. We also offer detailed layout drawings and customized technical advice upon request.

Need project-specific advice? Contact us.

Features of Chicken Mesh Machine

This forward-reverse twisted chicken mesh machine is reasonably designed, simple in structure, runs smoothly, performs well, and is easy to maintain.

Durable Mechanical Structure

The chicken mesh machine features high-strength steel, ensuring long-lasting durability and low maintenance. Key components are made from wear-resistant materials, allowing the machine to handle heavy daily use with reliability.

Automatic Stop Function

With wire break detection, chicken mesh machine stops automatically upon detecting broken wire or mesh damage, ensuring a flat and uniform mesh surface.

High Production Efficiency

Designed for continuous high-speed weaving, this chicken mesh machine rapidly produces large volumes of mesh panels. It delivers consistent output to support a variety of applications such as animal fencing and infrastructure projects.

Wide Range of Applications

This versatile machine suits poultry farming, zoo enclosures, machinery guards, highway barriers, sports fencing, and roadside greenbelt protection.

Case of Chicken Wire Mesh Machine

The production video shows our chicken mesh machine in action at a customer site, giving you a clear insight into the production process and the quality of the finished mesh.

For more project examples, real-world applications, or expert advice on choosing the right forward-reverse twisted hexagonal mesh machine, contact us. We provide customized solutions to your needs.

Dispatch of Chicken Mesh Machine

Each forward-reverse twisted chicken mesh machine is securely packed in wooden crates for safe international shipping. We offer flexible delivery via sea or rail, with direct shipping to destinations in Africa, Asia, and South America.

Get Factory Price for Chicken Mesh Machine

We’re the original manufacturer — factory direct, no trading companies involved.

Our engineers will respond within 24 hours with a quote and professional advice.

Hexagonal Wire Mesh Machine Related Products

We offer a full range of equipment for producing hexagonal mesh, along with complete solutions tailored to different project needs and production capacities.