Small Hexagonal Wire Mesh Machine Description

Flexible small hexagonal wire mesh machine

This compact hexagonal mesh machine is perfect for producing hexagonal mesh with smaller mesh sizes and thinner wire diameters.

Suitable for a variety of wire materials such as PVC-coated, galvanized, and copper wires.

Capable of producing mesh sizes down to 3/8 inch (approximately 10 mm).

Its space-saving design and customizable settings make it ideal for applications such as insulation mesh, poultry fencing, and decorative crafts.

Small Hexagonal Wire Mesh Machine Specifications

The key technical specifications of our small hexagonal wire mesh machine include mesh size, wire diameter, max width, speed, motor power, weight, and dimensions. All customizable to your project needs.

| Specifications | Mesh Size | Wire Diameter | Max Mesh Width | Number of Twists | Production Speed | Motor Power | Weight | Dimensions (L×W×H) |

|---|---|---|---|---|---|---|---|---|

| 1/2″ | 15×18 mm | 0.38 – 0.9 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

| 3/4″ | 22×33 mm | 0.4 – 0.9 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

| 1″ | 27×41 mm | 0.4 – 1.1 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

| 1/1/4″ | 32×52 mm | 0.5 – 1.25 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

| 1/1/2″ | 39×61 mm | 0.5 – 1.4 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

| 2″ | 55×70 mm | 0.5 – 1.6 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

| 3″ | 78×86 mm | 0.6 – 2.0 mm | 2000 mm/ 3000 mm | 3 | 60 – 80 mesh/min | 2.2 kw | 2 t / 3 t | 4200 / 5200×2000×1400 mm |

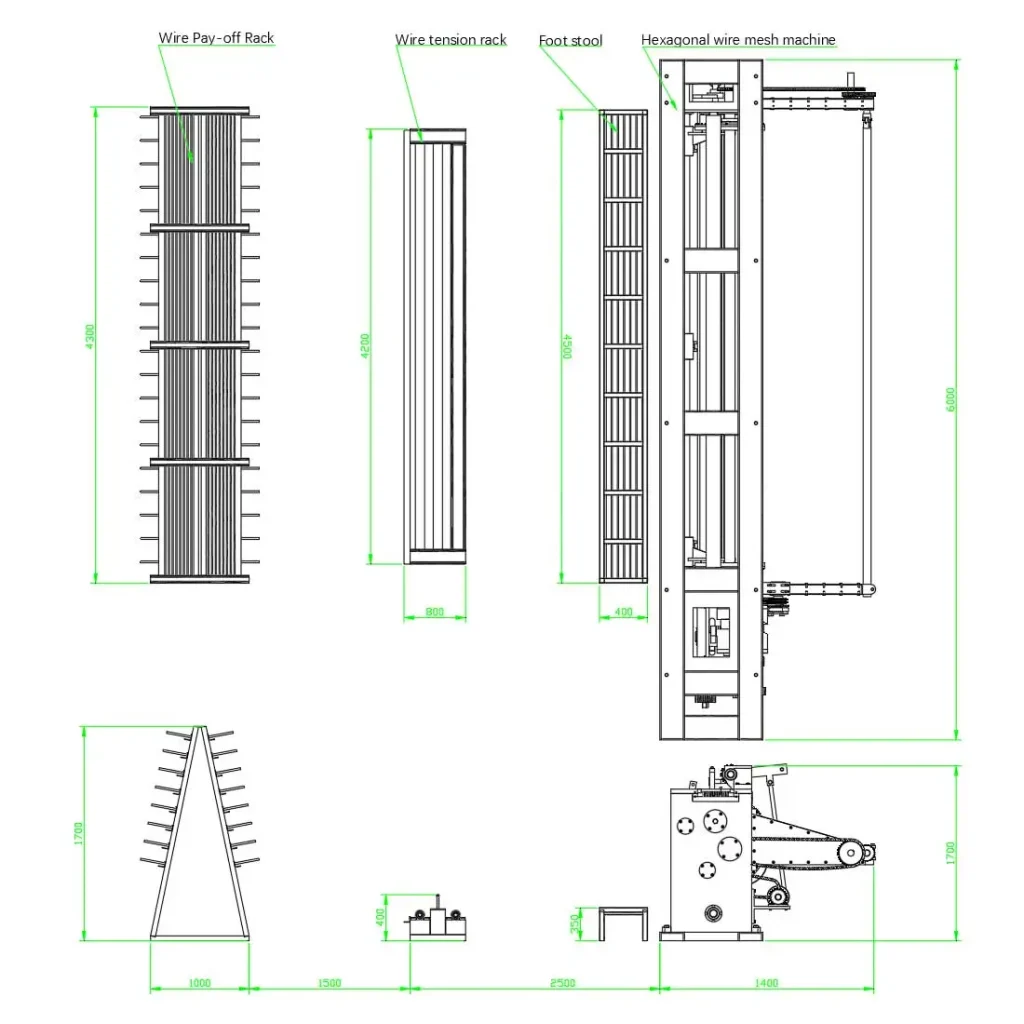

Small Hexagonal wire mesh machine layout drawing

The layout below helps illustrate the small hexagonal wire mesh machine setup and workshop planning, showing key units like the hexagonal mesh machine and pay-off stands. We also offer detailed layout drawings and customized technical advice upon request.

Need project-specific advice? Contact us.

Working Process of Small hexagonal Wire mesh machine

This section offers the operating procedures for a small hexagonal mesh machine. Our team is ready to assist you at any time to ensure safe and efficient use of your small hexagonal wire mesh machine.

You can get the operator’s manual for our small hexagonal wire mesh machines here.

Features Of Small Hexagonal Wire Mesh Machine

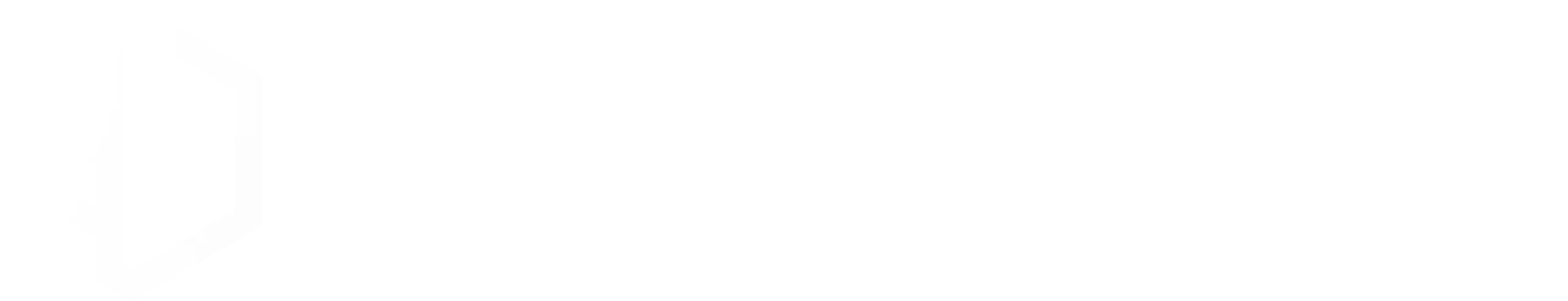

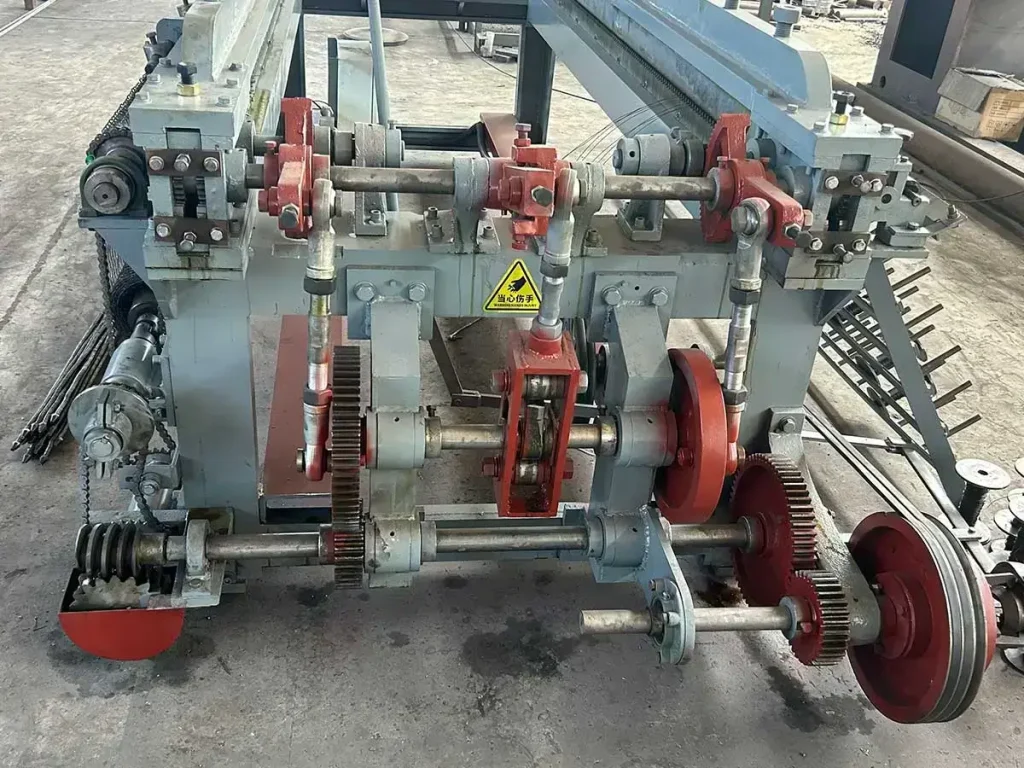

This small hexagonal wire mesh machine is reasonably designed, simple in structure, runs smoothly, performs well, and is easy to maintain.

Compact Line Laying Integration

The line laying frame connects directly to the small hexagonal mesh machine, eliminating the need for an additional thread tensioning system and significantly reducing floor space requirements.

Built-in Mesh Retrieval machine

A mesh roll-up mechanism is integrated beneath the small hexagonal mesh machine, eliminating the need for a separate recovery device to contract the hexagonal mesh and thereby simplifying the production process.

Case OF Small hexagonal Wire mesh machine

The production video showcases our small hexagonal wire mesh machine in action at a customer site, giving you a straightforward the production process and the quality of the finished mesh.

For more project examples, real-world applications, or expert advice on choosing the right small hexagonal mesh machine, contact us. We provide customized solutions to your needs.

Dispatch of Small Hexagonal Wire Mesh Machine

Each small hexagonal mesh machine is securely packed in wooden crates for safe international shipping. We offer flexible delivery via sea or rail, with direct shipping to destinations in Africa, Asia, and South America.

Get Factory Price for Small Hexagonal Mesh Machine

We’re the original manufacturer — factory direct, no trading companies involved.

Our engineers will respond within 24 hours with a quote and professional advice.

Hexagonal Wire Mesh Machine Related Products

We offer a full range of equipment for producing hexagonal mesh, along with complete solutions tailored to different project needs and production capacities.