PET Hexagonal Wire Mesh Machine Description

PET Hexagonal Wire Mesh Machine

The Polyester Hexagonal Mesh Machine weaves durable hexagonal mesh using PET polyester material, commonly known as tortoise shell mesh.

Hexagonal mesh woven from PET has high shrinkage, requiring heat treatment to stabilize its shape. To address this, a heating water tank is installed at the mesh outlet for softening and setting the mesh.

Cages made from PET hexagonal mesh offer excellent resistance to waves and biofouling, ensure optimal water flow, and deliver a long service life of 15–20 years. It is ideal for deep-sea aquaculture.

PET Hexagonal Wire Mesh Machine Specifications

Below are the key technical specifications of pet hexagonal mesh machine. These include mesh size, wire diameter, max mesh width, twist type, production speed, motor power, and overall machine size and weight. All parameters can be customized to meet your specific project requirements.

| Mesh Size | Wire Diameter | Max Mesh Width | Number of Twists | Production Speed | Motor Power | Weight | Dimensions (L×W×H) |

|---|---|---|---|---|---|---|---|

| 30×40 mm | 2.0 – 4.0 mm | 2000 mm | 3 | 60 m/h | 7.5 kw | 4 t | 4000×2500×1600 mm |

| 30×40 mm | 2.0 – 4.0 mm | 3000 mm | 3 | 60 m/h | 7.5 kw | 5 t | 5000×2500×1600 mm |

| 40×43 mm | 2.0 – 4.0 mm | 2000 mm | 3 | 65 m/h | 7.5 kw | 4 t | 4000×2500×1600 mm |

| 40×43 mm | 2.0 – 4.0 mm | 3000 mm | 3 | 65 m/h | 7.5 kw | 5 t | 5000×2500×1600 mm |

| 50×70 mm | 2.0 – 4.0 mm | 2000 mm | 3 | 72 m/h | 7.5 kw | 4 t | 4000×2500×1600 mm |

| 50×70 mm | 2.0 – 4.0 mm | 3000 mm | 3 | 72 m/h | 7.5 kw | 5 t | 5000×2500×1600 mm |

| 80×100 mm | 2.0 – 4.0 mm | 2000 mm | 3 | 80 m/h | 7.5 kw | 4 t | 4000×2500×1600 mm |

| 80×100 mm | 2.0 – 4.0 mm | 3000 mm | 3 | 80 m/h | 7.5 kw | 5 t | 5000×2500×1600 mm |

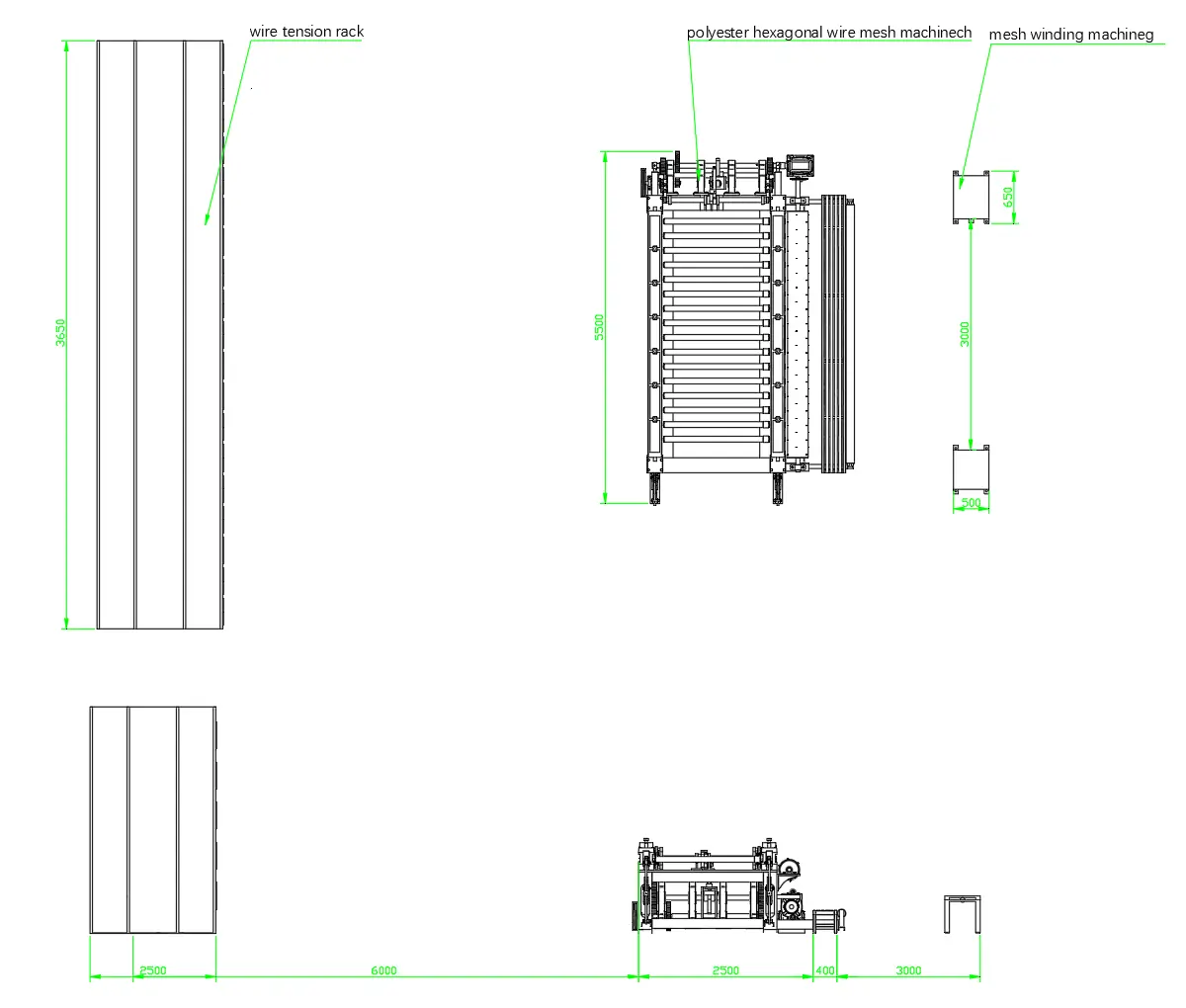

PET Hexagonal Wire Mesh Machine Layout Drawing

The layout below helps illustrate the PET hexagonal wire mesh machine setup, showing key units like the polyester hexagonal mesh machine, tension rack, and pay-off stands. We also offer detailed layout drawings and customized technical advice upon request.

Need project-specific advice? Contact us.

Working Process of peT hexagonal Wire mesh machine

This section offers a clear overview of the PET hexagonal wire mesh machine’s operating procedures. Our team is ready to assist you at any time to ensure safe and efficient use of your polyester hexagonal wire mesh machine.

You can get the operator’s manual for our PET hexagonal wire mesh machines here.

Features Of PET Hexagonal Wire Mesh Machine

This PET hexagonal wire mesh machine is well-designed, simple in structure, runs smoothly, has excellent performance, and is easy to maintain.

Simple Thread Loading

Using a fully automatic threading frame, production starts by simply loading polyester thread from the supplier; no secondary processing is needed.

Optional Auto Cutting machine

An optional automatic cutting machine enables precise mesh cutting at set lengths, followed by rolling and packaging.

Built-in Heating Tank

The machine includes a built-in heating water tank that allows temperature control for softening and shaping the woven mesh.

Flexible Operation Modes

The system supports both point motion and continuous operation for real-time adjustment of mesh shape during production.

Case of PET Hexagonal Wire Mesh Machine

The production video below showcases our PET hexagonal wire mesh machine in action at a customer site, giving you a clear insight into the production process and the quality of the finished mesh.

For more project examples, real-world applications, or expert advice on choosing the right PET hexagonal wire mesh machine, contact us. We provide customized solutions to your needs.

Dispatch of PET hexagonal Wire mesh machine

Each PET hexagonal wire mesh machine is securely packed in wooden crates for safe international shipping. We offer flexible delivery via sea or rail, with direct shipping to destinations in Africa, Asia, and South America.

Get Factory Price for PET Hexagonal Mesh Machine

We’re the original manufacturer — factory direct, no trading companies involved.

Our engineers will respond within 24 hours with a quote and professional advice.

Hexagonal Wire Mesh Machine Related Products

We offer a full range of equipment for producing hexagonal mesh, along with complete solutions tailored to different project needs and production capacities.