PLC Hexagonal Wire Netting Machine Description

Advanced PLC Forward-Reverse Twisted Hexagonal Wire Netting Machine

Developed by our team, this automatic hexagonal wire netting machine features PLC control, high-precision components, and servo motors, combined with a refined mechanical design delivering industry-leading automation and performance.

Compared to a mechanical hexagonal wire netting machine, it offers lower noise, higher precision, and faster output.

The touchscreen interface allows for continuous operation and manual adjustment.

Integrated alarm system, production tracking, and data aggregation make it ideal for smart factory applications.

PLC Hexagonal Wire Netting Machine Specifications

The key technical specifications of our PLC automatic hexagonal wire netting machine include mesh size, wire diameter, max width, speed, motor power, weight, and dimensions. All customizable to your project needs.

| Parameter | Specification |

|---|---|

| Specifications | 1/2″ , 3/4″ , 1″ , 1/1/4″ , 1/1/2″ , 2″ , 3″ , 4″ |

| Wire Diameter | 0.38 – 2.0 mm |

| Max Mesh Width | 2000 mm , 3000 mm , 4000 mm |

| Number of Twists | 6 |

| Production Speed | 180 m/h |

| Motor Power | 15.5 kW |

| Weight | 3.0 – 3.5 t |

| Dimensions (L×W×H) | 4200×1500×1600 mm , 5200×1500×1600 mm , 6200×1500×1600 mm |

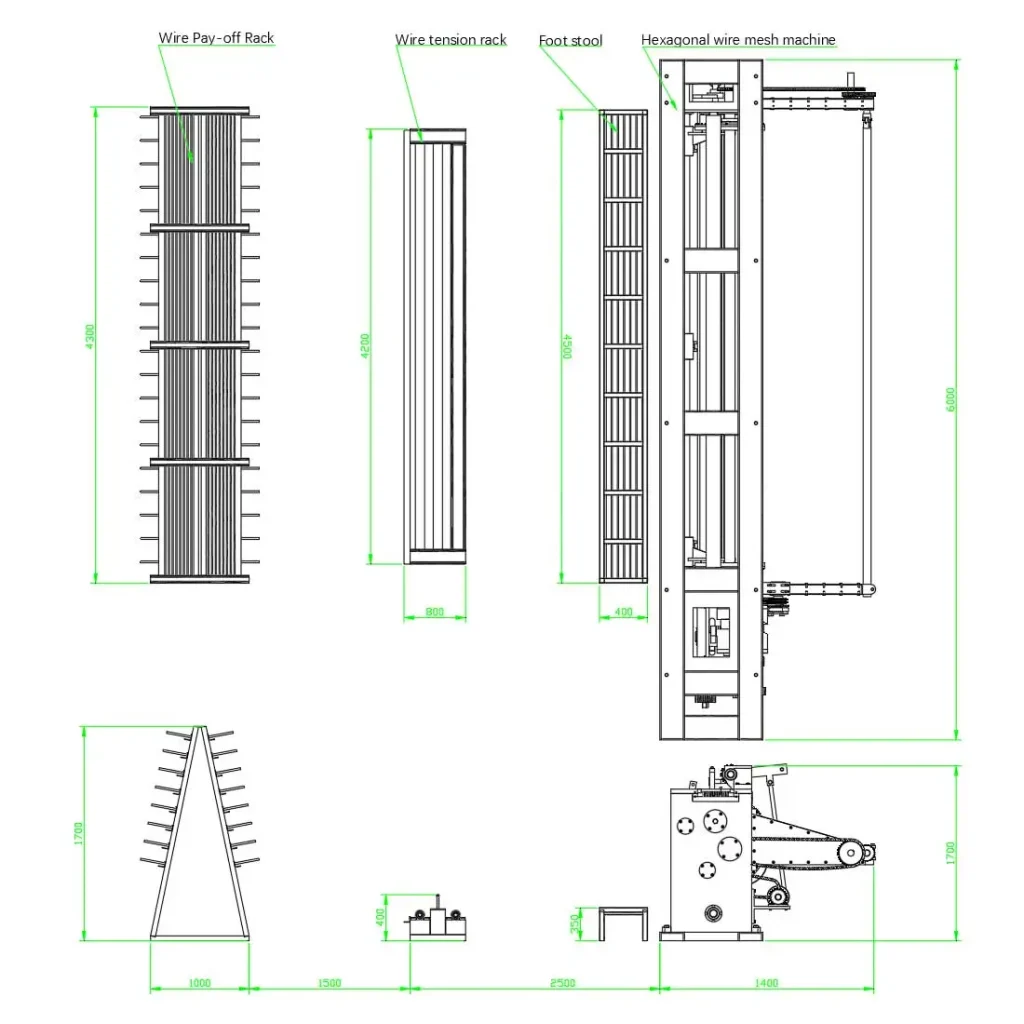

PLC Hexagonal Wire Netting Machine Layout Drawing

The layout below helps illustrate the automatic forward-reverse twisted hexagonal wire netting machine setup and workshop planning, showing key units like the automatic hexagonal mesh machine, tension rack, and pay-off stands. We also offer detailed layout drawings and customized technical advice upon request.

Need project-specific advice? Contact us.

Features of Automatic Hexagonal Wire Netting Machine

This automatic forward-reverse twisted hexagonal wire netting machine is reasonably designed, simple in structure, runs smoothly, performs well, and is easy to maintain.

Fault Protection Function

Automatically stops the hexagonal mesh machine and triggers an alarm if motor overload, preventing structural damage and displaying fault location on the screen.

Position Memory Function

Allows the machine to pause at any stage without losing position, enabling convenient and accurate start-stop operations.

Power Failure Protection

In case of sudden power loss, the system records the stop position for a smooth restart without adjustment after power is restored.

Reset and Recovery Function

Restores factory settings with one click when system disorder occurs; simply adjust to a preset position and resume regular operation easily.

Case of PLC Hexagonal Wire Netting Machine

The production video below showcases our automatic hexagonal wire netting machine in action at a customer site, giving you a clear insight into the production process and the quality of the finished mesh.

For more project examples, real-world applications, or expert advice on choosing the right automatic forward-reverse twisted hexagonal wire mesh machine, contact us. We provide customized solutions to your needs.

Dispatch of PLC Hexagonal Wire Netting Machine

Each automatic forward-reverse twisted hexagonal wire netting machine is securely packed in wooden crates for safe international shipping. We offer flexible delivery via sea or rail, with direct shipping to destinations.

Get Factory Price for Hexagonal Mesh Machine

We’re the original manufacturer — factory direct, no trading companies involved.

Our engineers will respond within 24 hours with a quote and professional advice.

Hexagonal Wire Mesh Machine Related Products

We offer a full range of equipment for producing forward-reverse twisted hexagonal mesh, along with complete solutions tailored to different project needs and production capacities.